Siirtola Well Constructs Two Basic Types of Wells:

1) Screened Well: water supply wells that are installed in unconsolidated sand and gravel aquifers and fitted with a screen,

2) Rock Well: water supply wells that are developed in fractured, jointed, or cavernous bedrock. Rock wells comprise the majority of water supply wells in the Keweenaw.

The geological conditions determine the type of well construction. Groundwater conditions and geological formations vary greatly from location to location in our 4-county area, and one well could differ significantly from a neighboring well hundreds of feet away. Although we may have an educated guess based on years of experience, we will not know with certainty until the drilling progresses if we will find water-bearing sand and gravel, or if drilling will need to continue through bedrock.

SCREENED WELLS

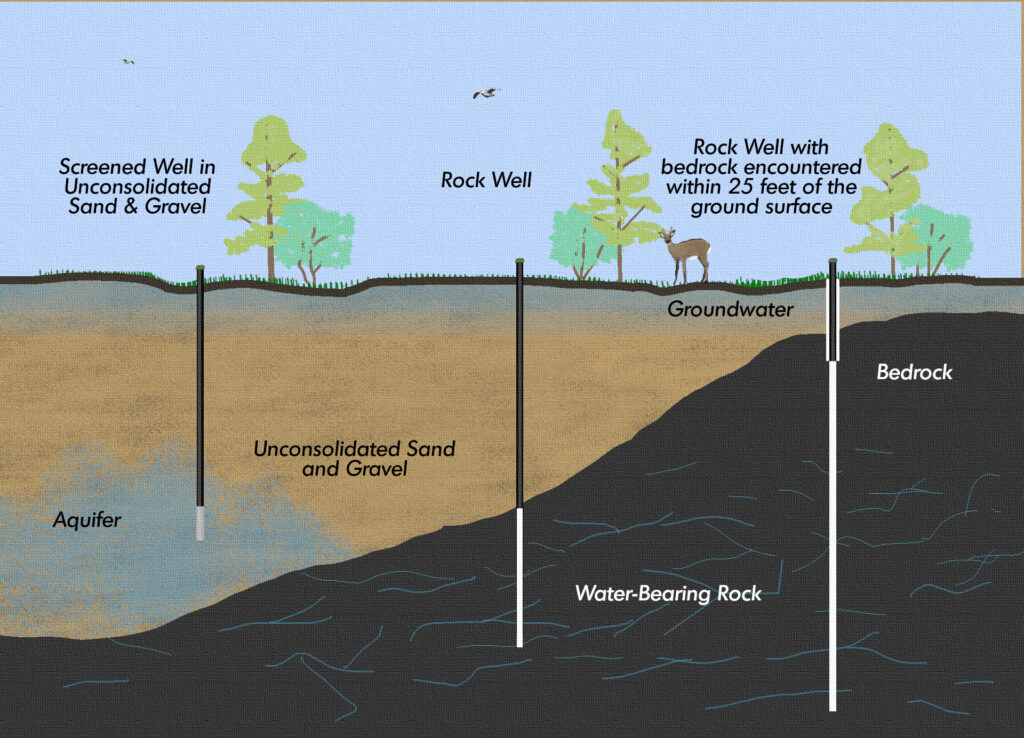

A screened well is one in which the water is obtained from a water bearing sand formation. The well is drilled and steel casing is installed down through the topsoil, clay, silt, sand and gravel until an aquifer is encountered. And then a screen is attached to the end of the casing and the well is developed to remove the fine sand near the screen so that the water can flow into the well. (See example well depicted on the left of the illustration above.)

According to Michigan Well Construction Code R 325.1639 Rule 139. (1):

A water supply well that is installed in unconsolidated sand and gravel aquifers shall ordinarily be fitted with a screen that has openings which are properly sized so that the aquifer can be properly developed to produce sand-free water at the pumping rate of the permanent pump.

ROCK WELLS

A rock well is one which terminates in shale, basalt, sandstone or limestone. Such a well is drilled in an area where no water bearing sand is found above the rock. The well is drilled with steel casing installed until bedrock is encountered, a tight joint is made where the pipe drive shoe contacts the rock, and then drilling begins in the rock.

In an area where a well can be developed only in fractured, jointed, or cavernous bedrock, the casing may terminate in the formation if there is not less than 25 feet of soil above the bedrock. (R 325.1637 Rule 137. (2)) (See example well depicted in the middle of the illustration above.)

Where bedrock is encountered within 25 feet of the ground surface, an oversized borehole will be drilled and the permanent casing will be grouted with neat cement for a minimum depth of 25 feet. (R 325.1637 Rule 137. (1)) (See example well depicted on the right of the illustration above.)

Drilling continues downward until sufficient water is obtained from cracks and crevices throughout the borehole. Siirtola Well uses a down-the-hole hammer that strikes at about 600 blows per minute to create openings to existing water-bearing cracks and crevices. (This is NOT hydrofracturing.) We will assess water production and will develop the well as necessary to improve the recovery rate. We will advise the client if the water production is adequate based on the intended use and the depth of the well.

LOW-PRODUCING WELLS

A low-producing well, even with as little as 1/2 gallons per minute, may be sufficient for household use if there is an adequate reservoir, which is dependent on the depth of the borehole and the static water level.

According to the State of Michigan Water Well Manual:

The area geology determines how successful a well drilling contractor may be in obtaining a suitable water supply from a well. … According to the Well Construction Code in Michigan, there is no minimum gallons per minute a well must produce. This is because a few areas of the state (e.g., “Thumb,” Upper Peninsula, and SE Michigan) have groundwater conditions that do not produce more than just 2-3 gpm. … Generally, [a low-producing well] is considered one with a production rate of less than 5 gpm. Most areas of Michigan provide well owners with more than enough well water to meet their needs. However, there are a few areas (e.g., the “Thumb,” far southeast Michigan, certain areas of the Upper Peninsula, etc.) that produce less than 5 gpm. (Re: Water Well Manual August 2023)

WELL DEVELOPMENT

Siirtola Well will develop the well to increase the production of water and remove large sediment and shavings from the drilling process. Before installing the permanent pump, Siirtola Well will pump to waste the well until the water is as clear as is reasonably possible considering the groundwater conditions in the area. This process generally takes between 1 and 8 hours until the well is in such a condition where the permanent pump can be used without damage to it.

According to the Michigan Well Construction Code Administrative R 325.1637 Rule 139. (5):

A new, repaired, or reconditioned well shall be developed and pumped to waste at a pumping rate which equals or exceeds that of the permanent pump, until the water is as clear as is reasonably possible considering the groundwater conditions in the area. The permanent pump shall not be used to develop the well without the owner’s consent.

We would expect that a screened well could be developed until it is sand-free, although there may be some turbidity until the well is put into regularly use and stabilizes. Michigan Well Construction Code R 325.1639 Rule 139 (1) states:

A water supply well that is installed in unconsolidated sand and gravel aquifers shall ordinarily be fitted with a screen that has openings which are properly sized so that the aquifer can be properly developed to produce sand-free water at the pumping rate of the permanent pump.

Rule 139 (1) applies only to wells “installed in unconsolidated sand and gravel aquifers” and fitted with a screen. Rock wells do not terminate in unconsolidated sand and gravel, and a regular screen cannot be installed in a rock well. Rock wells can continue to produce sand and turbidity, particularly if they are pumped too hard.

PUMPING SYSTEMS AND WELL STABILIZATION

Once your well is drilled, you will need a pumping system to move the water. In most drilled wells, a submersible pump is installed. A properly installed pumping system will give years of dependable service. Included in the base well construction service, Siirtola Well will clear the well of all sediment that could damage a residential pump, and thereafter can continue to develop the well at our hourly service rate. That process to further develop the well involves pumping it slowly with a garden hose, and well owners may elect to have the permanent pump installed and proceed with stabilizing the well on their own with instruction from Siirtola Well.

According to the Michigan Department of Environmental Quality:

New wells occasionally pump a small amount of sand or turbidity (ST) initially. Once a well is put into routine service the intake area generally stabilizes. Sand grains bridge on the outside of the well screen and sand production ceases. Existing wells can occasionally develop sand/turbidity (ST) problems after several years of service. … Increased pump capacity will increase water entrance velocity into the well, enabling the water to carry sand into the well. … No single approach will solve all ST problems. Some are easily cured while others can be stubborn. It is important to determine whether the ST problem is an isolated case or if it is surrounded by other wells with the same problem. … If the ST problem is present because of geological limitations and the well has been properly designed, correction options may be limited. Sediment filters and sand separators do not correct the source of the problem, but can be effective at preventing particles from reaching the water distribution system. Their use should be considered only if the ST problem is geologically controlled. (Re: November 1998 Letter)

The geological limitations of rock wells can create sand and turbidity for days, weeks or months after a well was initially developed and cleared of larger sediment and shavings from the drilling process. In cases where the ST problem is geologically controlled, sediment filters and sand separators can be effective at preventing particles from reaching the water distribution system. We can advise the client of methods to obtain clearer water by slowly pumping the well, or we can refer the client to other companies that provide filtration systems.

PROBLEMATIC FORMATIONS AND GROUNDWATER CONDITIONS

Siirtola Well will advise the well owner if problematic formations or groundwater conditions are encountered:

In the case of the low-producing wells without an adequate reservoir, Siirtola Well can install above-ground tanks to provide sufficient capacity for periods of peak demand.

In the event of caving formations, slotted steel or PVC pipe can be used to hold back the borehole walls and protect the pump. Slotted pipe does not serve the same purpose as a traditional screen to filter sand from a well, and we would not expect this sort of rock well to be completely free of sand, as would be required of a screened well in unconsolidated sand and gravel aquifers, per R 325.1637 Rule 139. (1).

In some areas, we often encounter briny groundwater, but the water may still be usable for bathing and cleaning. Siirtola Well can provide referrals for companies that can install filtration systems to obtain potable water.

Due to regulatory hurdles, Siirtola Well avoids constructing wells in areas known to have flowing wells, but if flowing artesian conditions are encountered, R 325.1638 Rule 138 requires:

(1) A well that is constructed in a location where flowing artesian conditions are encountered or are expected to occur shall be grouted to protect the artesian aquifer, prevent erosion of overlying geologic materials, and confine the flow to within the casing.

(2) Flowing well discharge control shall be provided to conserve groundwater and to prevent the loss of artesian head by preventing or reducing continuous discharges, unless a deviation is issued pursuant to the provisions of R 325.1613. Flow control shall consist of valved pipe connections, watertight pump connections, a receiving tank that is set at an altitude corresponding to that of the artesian head, a flowing well pitless adapter, a packer, or other method approved by the health officer. A flow discharge pipe, where installed, shall not be directly connected to a sewer or other source of contamination.

R 325.1613 allows for deviation from the provisions of R 325.1638 (2) to permit flowing well discharge if the well owner or the well owner’s representative demonstrates any of the following: (i) Control of the flow is not practical. (ii) Control of the flow will likely result in the production of sand or turbidity in the water. (iii) The discharge is for a beneficial use.

References:

Gaber, Michael, Chief Well Construction Unit, Drinking Water and Radiological Protection Division. “Letter to Local Health Departments Attn: Environmental Health Directors, Supervising Sanitarians, Field Sanitarians Subject: Water Wells Producing Sand or Turbidity.” November 25, 1998. State of Michigan Department of Environmental Quality, Lansing Michigan. PDF.

https://www.michigan.gov/egle/-/media/Project/Websites/egle/Documents/Programs/DWEHD/Water-Well-Construction/Correspondence/Letter-1998-11-25-Water-Wells-Producing-Sand-or-Turbidity.pdf?rev=053d5e171e034055b4682e6e16e3af88

Michigan Department of Environment, Great Lakes, and Energy (EGLE). “State of Michigan Water Well Manual.” August 2023. Environmental Health Section, Source Water Unit, Well Construction Program. Department of Environment, Great Lakes, and Energy Water Well Construction https://www.michigan.gov/-/media/Project/Websites/egle/Documents/Programs/DWEHD/Water-Well-Construction/Water-Well-Manual.pdf?rev=6a20f28815644913a502a27450fefb86

Michigan Department of Public Health. “Well Construction Code Administrative Rules.” Filed with the Secretary of State on April 5, 1994. PDF. https://www.michigan.gov/-/media/Project/Websites/egle/Documents/Programs/DWEHD/Water-Well-Construction/Well-Code-Administrative-Rules.pdf?rev=b8c2616b477e49c599e7b64fee5aaf6f